Big data manufacturing is transforming how factories operate, make decisions, and ensure quality. In today’s era of digital transformation, manufacturers face growing pressure to produce faster, cheaper, and with greater precision. Through advanced analytics and real-time monitoring, organizations can now collect and interpret massive volumes of production data to identify inefficiencies, prevent downtime, and optimize performance at every stage of the process.

Understanding Big Data in Manufacturing

In the context of Industry 4.0, big data manufacturing refers to the systematic collection, integration, and analysis of large datasets generated across production lines. These datasets include everything from machine sensor readings and equipment health indicators to supply-chain metrics and quality inspection data. By connecting equipment and processes through the Industrial Internet of Things (IIoT), companies gain continuous visibility into their operations.

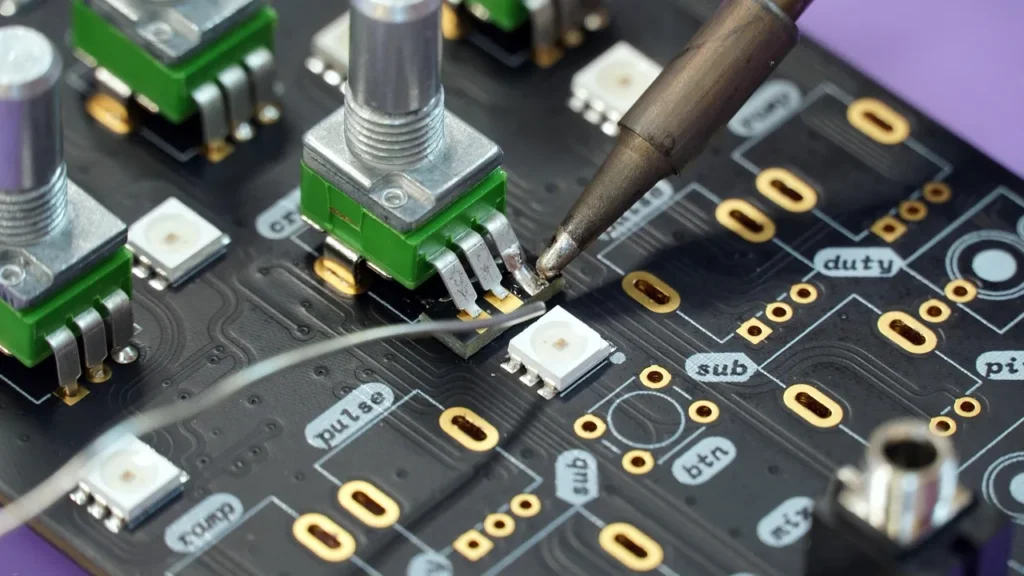

Unlike traditional production methods, which rely on periodic checks or manual oversight, data-driven factories operate in real time. Every movement of a conveyor, temperature change in a furnace, or vibration in a robotic arm is captured, stored, and analyzed within milliseconds. This allows manufacturers to make proactive decisions—adjusting parameters before defects occur, or anticipating maintenance needs before machines fail.

The Role of Industrial Analytics

Collecting data is only the first step; turning it into actionable intelligence is where the real value lies. Analytics in big data manufacturing converts raw data streams into meaningful insights that guide continuous improvement. Descriptive analytics explains what happened, diagnostic analytics explores why it happened, predictive analytics forecasts what is likely to happen, and prescriptive analytics suggests how to respond.

For example, a predictive algorithm might detect that a machine’s vibration frequency pattern matches those observed prior to bearing failure. This triggers an alert for preventive maintenance, avoiding costly unplanned downtime. As noted in the McKinsey Manufacturing Insights Report, data-driven analytics can improve overall equipment effectiveness (OEE) by up to 20 percent through smarter maintenance and production scheduling.

Components of a Big Data Manufacturing System

Building a successful big data manufacturing framework requires integrating multiple layers of technology—from sensors to cloud platforms—that work together seamlessly. These layers enable factories to capture, process, and act on data instantaneously.

Core Technologies Enabling Big Data

- IoT Sensors and Edge Devices: These collect high-frequency data on temperature, pressure, speed, vibration, and energy usage, providing the foundation for accurate monitoring.

- Cloud and Edge Computing: Edge computing processes data locally for speed, while cloud platforms handle large-scale analytics and long-term storage.

- Artificial Intelligence and Machine Learning: AI models recognize patterns and optimize production parameters without human intervention.

- Data Visualization and Dashboards: Tools such as MES (Manufacturing Execution Systems) or SCADA display live performance indicators that guide operators’ decisions.

Real-Time Monitoring and Control

Real-time monitoring is the heart of modern manufacturing intelligence. Through digital dashboards, supervisors can track key metrics such as throughput, defect rates, and machine utilization in live mode. Deviations trigger automated responses—machines slow down, adjust torque, or recalibrate sensors—to maintain consistent quality.

Digital twins further enhance this capability by creating virtual replicas of physical assets. Engineers can simulate process changes and predict outcomes before applying them on the production floor. This continuous feedback loop allows factories to achieve higher precision while minimizing waste and energy consumption.

Benefits of Big Data in Manufacturing

Adopting big data manufacturing strategies provides measurable benefits across efficiency, quality, and profitability. The integration of analytics and monitoring enables manufacturers to detect subtle process deviations, predict maintenance needs, and optimize resource usage—all in real time.

Efficiency, Quality, and Cost Optimization

- Predictive Maintenance: Continuous data analysis detects anomalies and schedules maintenance before breakdowns occur, cutting downtime and repair costs.

- Enhanced Quality Control: Automated inspection systems compare real-time production data with quality standards, identifying defects early in the process.

- Process Optimization: Analytics reveals bottlenecks, helping managers rebalance workloads and streamline throughput.

- Resource Management: Live energy and material consumption tracking reduces waste and environmental footprint.

According to recent studies, factories using big data manufacturing techniques achieve productivity improvements of 15–25 percent. The result is a more agile, resilient, and sustainable manufacturing ecosystem capable of responding rapidly to market fluctuations.

Case Example: Smart Factory Implementation

Consider a global automotive supplier implementing an end-to-end big data manufacturing solution. By installing hundreds of IoT sensors on its stamping and assembly lines, the company gathered millions of data points daily. Using advanced analytics, it identified small inefficiencies—like millisecond delays between robotic arms—that previously went unnoticed.

Through real-time monitoring dashboards, managers tracked metrics such as OEE, defect rates, and machine cycle times. Within six months, defect rates fell by 12%, unplanned downtime dropped by 18%, and throughput increased substantially. These gains were achieved without adding new equipment—only by leveraging data more intelligently.

Challenges in Big Data Manufacturing

While the potential of big data manufacturing is immense, many organizations encounter significant challenges when deploying large-scale digital systems. Data volume and complexity continue to grow exponentially, making storage, processing, and interpretation difficult. Factories must deal with diverse machine protocols, legacy systems, and unstructured datasets that often sit in isolated silos, hindering holistic analysis.

Cybersecurity is another major concern. Connected devices, sensors, and cloud platforms expand the attack surface, exposing production lines to potential breaches. Establishing robust firewalls, encrypted communication, and role-based access control is vital to protecting proprietary data. Moreover, ensuring data accuracy and consistency across multiple collection points remains a persistent issue that directly affects the reliability of analytics and monitoring outcomes.

Addressing the Barriers

- Unified Data Platforms: Consolidating machine, process, and enterprise data into a centralized platform eliminates silos and streamlines decision-making.

- Advanced Cybersecurity Protocols: Regular audits, multi-factor authentication, and anomaly detection systems help safeguard industrial networks.

- Skilled Workforce Development: Upskilling employees in data science, visualization, and automation ensures that teams can interpret analytics effectively.

- Scalable Infrastructure: Combining on-premise edge systems with cloud computing provides flexibility for handling both high-speed and long-term analytics workloads.

Integrating Real-Time Monitoring with Production

Modern big data manufacturing systems rely on continuous monitoring loops that connect machines, operators, and management dashboards. Every event in the factory—temperature changes, torque variations, or power fluctuations—triggers instant feedback to optimize operations. When combined with predictive analytics, this data transforms manufacturing into a self-correcting environment.

For example, when a machine tool slightly deviates from its normal vibration pattern, sensors transmit the anomaly to an AI model that compares it against historical data. If the model predicts an imminent failure, the system automatically schedules maintenance or adjusts speed to prevent damage. This proactive process eliminates costly downtime and extends equipment lifespan.

Digital Twins and Simulation

The emergence of digital twin technology marks a new era in big data manufacturing. A digital twin is a virtual replica of a physical asset or process that mirrors real-time performance data. Engineers can simulate process changes, test “what-if” scenarios, and evaluate the impact of new parameters before applying them to the actual equipment. This capability not only reduces risk but also accelerates innovation and product development cycles.

Data Analytics for Continuous Improvement

The integration of advanced analytics enables continuous improvement methodologies such as Six Sigma and Lean Manufacturing to operate on real-time data rather than retrospective reports. Key performance indicators (KPIs) like cycle time, scrap rate, and yield can now be tracked minute-by-minute, empowering teams to respond instantly to deviations.

Machine-learning algorithms also reveal hidden relationships between variables. For instance, a minor humidity fluctuation might correlate with a spike in defect rates during surface coating. Once identified, this insight allows engineers to adjust humidity control systems and eliminate recurring issues. This level of precision drives measurable quality gains and cost savings.

Future Trends in Big Data Manufacturing

The next decade will redefine the landscape of big data manufacturing through smarter connectivity and automation. Several emerging technologies are poised to amplify the impact of real-time monitoring and analytics across industries.

1. Artificial Intelligence and Self-Optimizing Systems

AI will evolve from a decision-support tool into an autonomous control layer that self-adjusts production parameters. These systems can analyze thousands of data points per second, learning the optimal settings for yield, energy, and cost without human intervention.

2. 5G Connectivity and Edge Computing

Ultra-low latency communication made possible by 5G networks enables instant feedback loops between devices. Edge computing nodes positioned near machines process critical data locally, supporting real-time analytics even in bandwidth-limited environments.

3. Sustainability and Green Manufacturing

Big data manufacturing plays a vital role in achieving sustainability goals. Data-driven energy management systems track carbon emissions, optimize electricity usage, and monitor water consumption. Manufacturers can measure their environmental impact and implement strategies for carbon neutrality.

4. Interoperability and Open Data Ecosystems

Collaboration across supply chains will become increasingly important. Standardized communication protocols like OPC UA and MQTT allow different equipment vendors to exchange data seamlessly. This open-data approach enhances transparency, enabling end-to-end optimization from raw materials to finished goods.

Economic and Strategic Benefits

Companies embracing big data manufacturing are realizing strong competitive advantages. Data-centric decision-making improves forecasting accuracy, reduces inventory costs, and increases customer satisfaction. By combining predictive analytics with real-time monitoring, manufacturers gain the agility to adapt to market shifts and customize production with minimal waste.

According to industry research, organizations that fully integrate big data solutions can boost operating margins by up to 60 percent compared to traditional manufacturers. The return on investment extends beyond cost savings—improved safety, faster innovation cycles, and enhanced traceability build long-term resilience in global supply chains.

Conclusion

Big data manufacturing is redefining the foundation of modern production. Through intelligent analytics, continuous monitoring, and real-time control, factories evolve into adaptive, self-learning systems capable of delivering precision, efficiency, and sustainability. The fusion of data science and industrial engineering unlocks a new level of operational excellence that will shape the future of manufacturing worldwide.

As technology advances, success will depend on a clear digital strategy—integrating people, processes, and platforms into one cohesive data ecosystem. Manufacturers that embrace this transformation today will lead the next generation of smart, resilient, and data-driven industries.