AI in manufacturing is revolutionizing how factories operate, transforming production lines into intelligent ecosystems where machines learn, adapt, and improve continuously. With the rise of machine learning, robotics, and data-driven analytics, smart manufacturing is becoming the core of Industry 4.0—an era defined by automation, precision, and real-time decision-making. The integration of artificial intelligence into industrial operations is not only boosting productivity but also enabling predictive control, cost reduction, and sustainable growth across the global manufacturing sector.

Understanding AI in Manufacturing

Artificial Intelligence in manufacturing refers to the application of intelligent algorithms that mimic human cognition to make informed decisions within production environments. Unlike traditional automation that relies on pre-programmed commands, AI in manufacturing allows machines to analyze data, recognize patterns, and make adjustments autonomously. These capabilities are crucial for optimizing production, reducing errors, and increasing overall efficiency.

Core Components of an AI-Driven Factory

- Data Collection and IoT Sensors: Modern factories are equipped with thousands of sensors that monitor variables like temperature, vibration, and pressure, generating massive datasets in real time.

- Machine Learning Models: Algorithms process this data to identify patterns, anomalies, and trends that human operators might miss. Machine learning provides continuous improvement by adapting to changing production conditions.

- Autonomous Process Control: AI-driven systems can adjust speed, pressure, and tool settings automatically, reducing waste and ensuring consistent product quality.

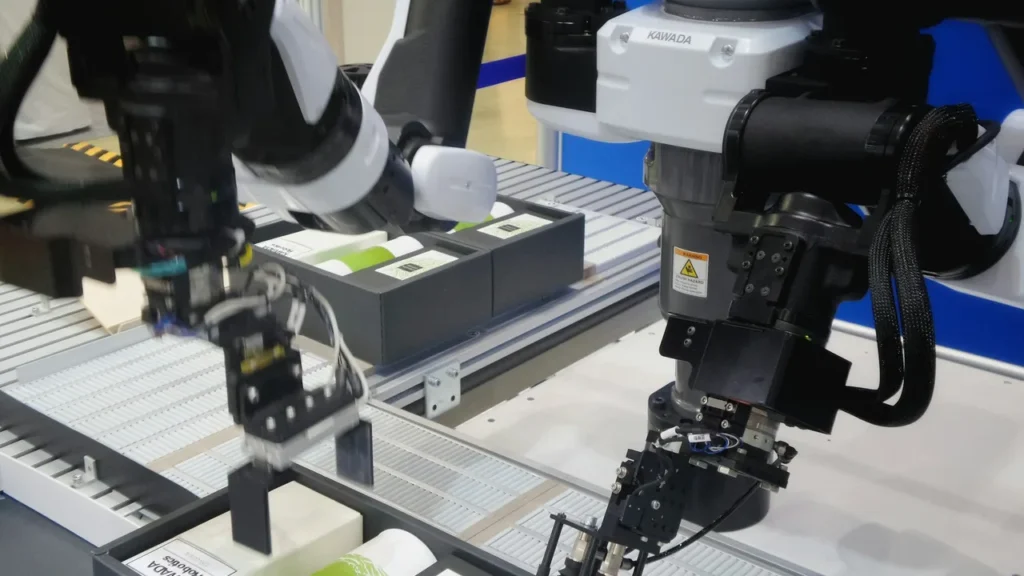

- Human-Machine Collaboration: Cobots (collaborative robots) work safely alongside humans, combining human intuition with machine precision.

This interconnected ecosystem forms the foundation of smart manufacturing, where machines act not just as tools but as intelligent partners capable of self-optimization and predictive decision-making.

The Evolution Toward Smart Manufacturing

Manufacturing has evolved dramatically over the past century—from mechanization during the First Industrial Revolution to today’s fully digitalized smart factories. In this journey, AI in manufacturing represents the ultimate step: the shift from automation to autonomous intelligence. Smart factories integrate cloud computing, real-time data analytics, and robotic systems that work together seamlessly, eliminating inefficiencies and enhancing scalability.

Role of Data and Connectivity

Data is the lifeblood of modern manufacturing. Without accurate and timely information, even the most advanced AI system cannot function effectively. Through the Internet of Things (IoT), every piece of equipment, conveyor belt, and robotic arm becomes a data node contributing to the collective intelligence of the factory. This data-centric approach enables continuous improvement, faster response times, and smarter decision-making. According to the MIT Sloan School of Management, data-driven manufacturing will define competitiveness in the coming decade.

Machine Learning: The Brain of Smart Manufacturing

Machine learning is at the heart of intelligent production systems. It empowers machines to learn from data without being explicitly programmed, enabling continuous optimization of complex industrial processes. In AI in manufacturing, ML models are used for tasks such as quality prediction, supply chain optimization, and energy management. By training algorithms on historical and real-time production data, factories can detect inefficiencies and predict potential disruptions before they occur.

Types of Machine Learning Used in Industry

- Supervised Learning: Uses labeled datasets to predict outcomes like defect rates or machine performance levels.

- Unsupervised Learning: Identifies hidden patterns in unlabeled data, useful for clustering and anomaly detection.

- Reinforcement Learning: Teaches robots to make decisions based on trial and error, improving over time through feedback loops.

The adoption of machine learning has redefined how factories analyze performance metrics. Instead of relying on static parameters, dynamic models adjust to variations in materials, labor conditions, and energy usage, enabling a more flexible production environment.

Benefits of Machine Learning Implementation

| Area | Benefit |

|---|---|

| Quality Control | AI-powered vision systems detect micro-defects in real time, reducing rework and material waste. |

| Production Efficiency | Machine learning optimizes line speed, tool wear, and process parameters dynamically. |

| Cost Reduction | Predictive algorithms identify energy-saving opportunities and minimize equipment downtime. |

Predictive Maintenance and Operational Efficiency

One of the most transformative applications of AI in manufacturing is predictive maintenance. By continuously monitoring machine conditions through vibration, temperature, and acoustic sensors, AI models can forecast potential failures long before they happen. This allows manufacturers to schedule maintenance proactively, reducing unplanned downtime and avoiding costly production halts.

Predictive maintenance goes beyond simple alerts—it enables optimization of spare parts inventory, technician scheduling, and resource allocation. In modern factories, machine learning algorithms analyze billions of data points to predict when a specific component will fail, ensuring that replacement happens precisely when needed, not too early or too late.

Practical Benefits of Predictive Maintenance

- Reduces total maintenance costs by up to 30%.

- Extends equipment lifespan through optimized usage cycles.

- Improves workplace safety by preventing mechanical accidents.

- Increases sustainability by minimizing material waste and energy loss.

By combining predictive maintenance with other AI applications like computer vision and robotics, manufacturers are creating ecosystems that learn, anticipate, and adapt—turning data into actionable intelligence for continuous improvement.

Applications of AI Across the Manufacturing Chain

The impact of AI in manufacturing extends across every stage of the production cycle—from raw-material planning to customer delivery. Artificial intelligence improves traceability, coordination, and control, creating an end-to-end intelligent ecosystem that connects suppliers, factories, and logistics networks.

Key Use Cases of AI in Manufacturing

- Quality Control and Inspection: Vision systems equipped with machine learning algorithms analyze thousands of images per second to detect surface defects, misalignments, or dimensional errors that human eyes might miss.

- Supply-Chain Optimization: Predictive analytics anticipates demand fluctuations, helping managers adjust procurement and inventory in real time.

- Production Scheduling: Dynamic scheduling engines powered by AI balance machine loads, shift patterns, and maintenance windows for maximum efficiency.

- Smart Robotics: Adaptive robots learn new assembly routines through reinforcement learning, reducing programming time and improving flexibility on the shop floor.

Real-World Examples

In the automotive sector, computer-vision platforms now verify weld quality and paint consistency automatically, slashing rework rates by more than 20 percent. Electronics manufacturers apply machine learning to analyze solder-joint reliability, while pharmaceutical plants use AI-based environmental monitoring to maintain sterile production zones. Each case shows how intelligent algorithms translate data into measurable operational gains.

Challenges and Limitations

Despite its potential, adopting AI in manufacturing is not without barriers. Many factories still rely on legacy systems that lack data connectivity or standardized interfaces. Integrating AI solutions often requires upgrading sensors, networks, and control software—investments that can be costly for small and medium-sized enterprises.

Another limitation is data quality. Inconsistent or incomplete datasets can mislead machine learning models, resulting in inaccurate predictions. Furthermore, as production becomes more connected, cybersecurity threats grow, requiring robust protection against ransomware and industrial espionage. Finally, workforce adaptation remains a challenge: employees must acquire digital skills to collaborate effectively with AI-driven systems.

Strategies to Overcome the Challenges

- Upskilling the Workforce: Continuous training programs ensure technicians understand how to interpret AI insights and maintain intelligent systems.

- Cloud-Based AI Platforms: Leveraging software-as-a-service reduces infrastructure costs and allows small factories to access advanced analytics tools.

- Data Governance and Cybersecurity: Implementing clear data-collection standards and multilayer security safeguards industrial networks from breaches.

Future of AI-Driven Manufacturing

The next decade will mark the era of hyper-connected smart factories where AI in manufacturing integrates seamlessly with robotics, 5G connectivity, and digital twins. Virtual replicas of machines and processes will allow engineers to test scenarios before physical execution, minimizing risk and accelerating innovation. Predictive analytics will merge with autonomous robotics, creating production lines that self-adjust in real time to market changes.

Quantum Computing and Next-Gen Simulation

Emerging quantum algorithms promise to process complex optimization tasks—such as material composition and energy distribution—at speeds unattainable by classical computers. This leap could redefine everything from product design to predictive maintenance cycles, enabling near-instant decision making across the value chain.

Toward Sustainable Manufacturing

AI technologies are also central to sustainability. Intelligent energy-management systems monitor consumption patterns and automatically shut down idle equipment. Machine learning models identify waste sources and recommend process adjustments to reduce emissions. The result is a new generation of factories that are not only smart but also environmentally responsible.

Economic and Environmental Impact

The economic implications of adopting AI in manufacturing are immense. Companies implementing smart-factory initiatives report double-digit improvements in productivity, shorter product-development cycles, and reduced operational costs. From an employment perspective, AI creates demand for new roles—data scientists, automation engineers, and system integrators—while enhancing safety by transferring repetitive or hazardous tasks to machines.

Environmentally, intelligent manufacturing contributes to significant energy savings and emission reduction. Predictive control systems fine-tune heating, cooling, and material usage, cutting the carbon footprint of industrial plants. These advances align manufacturing growth with global climate goals, ensuring long-term sustainability.

Conclusion

AI in manufacturing represents a fundamental shift in how goods are designed, produced, and delivered. By merging human creativity with machine learning precision and predictive maintenance foresight, smart factories achieve unprecedented levels of efficiency and reliability. The ongoing evolution of artificial intelligence is not just automating tasks—it’s redefining the entire industrial landscape.

As technology continues to mature, manufacturers that embrace AI will lead the next wave of innovation, setting new benchmarks for quality, sustainability, and global competitiveness. The factory of the future is here—and it’s powered by intelligence.