The global energy industry is evolving rapidly, demanding high-performance, durable, and efficient infrastructure solutions. As power generation facilities expand to meet rising demand, the steel structure factories has become an essential component in modern energy construction. Combining structural precision with long-term reliability, these facilities form the backbone of turbine halls, boiler buildings, substations, and renewable energy centers worldwide.

The Role of Steel in the Energy Sector

Steel has long been the preferred material in power plant construction due to its exceptional strength, adaptability, and performance under extreme conditions. In the energy sector, where buildings must support heavy turbines, high-temperature boilers, and complex mechanical systems, structural integrity is non-negotiable. Steel’s superior load-bearing capacity ensures that these structures can handle massive dynamic forces while maintaining safety and stability.

Why Steel Is Indispensable in Power Generation

Whether for conventional thermal power plants or renewable energy facilities, steel offers unmatched versatility. It enables engineers to design expansive turbine halls with wide clear spans, tall frames, and integrated crane systems that simplify equipment installation and maintenance. Moreover, steel structures can withstand vibration, pressure, and temperature variations—key requirements in energy environments that operate around the clock.

Unlike concrete or brick, which can crack or deteriorate under thermal stress, steel’s ductility allows it to absorb energy without losing strength. This property makes it ideal for applications in turbine enclosures, generator rooms, and process plant buildings. Additionally, with advanced coatings and galvanization, steel structures resist corrosion, reducing maintenance cycles and extending operational life.

Steel vs. Conventional Materials

Comparing a steel structure factory to traditional concrete-based industrial facilities reveals clear advantages:

- Speed of Construction: Prefabricated steel components are manufactured off-site and assembled on-site, drastically reducing construction time.

- Weight Efficiency: Steel has a higher strength-to-weight ratio, allowing lighter frameworks to support heavy industrial equipment.

- Design Flexibility: Architects and engineers can create complex geometries and long spans without compromising structural integrity.

- Sustainability: Steel is recyclable, lowering the carbon footprint of energy projects.

Understanding the Steel Structure Factories

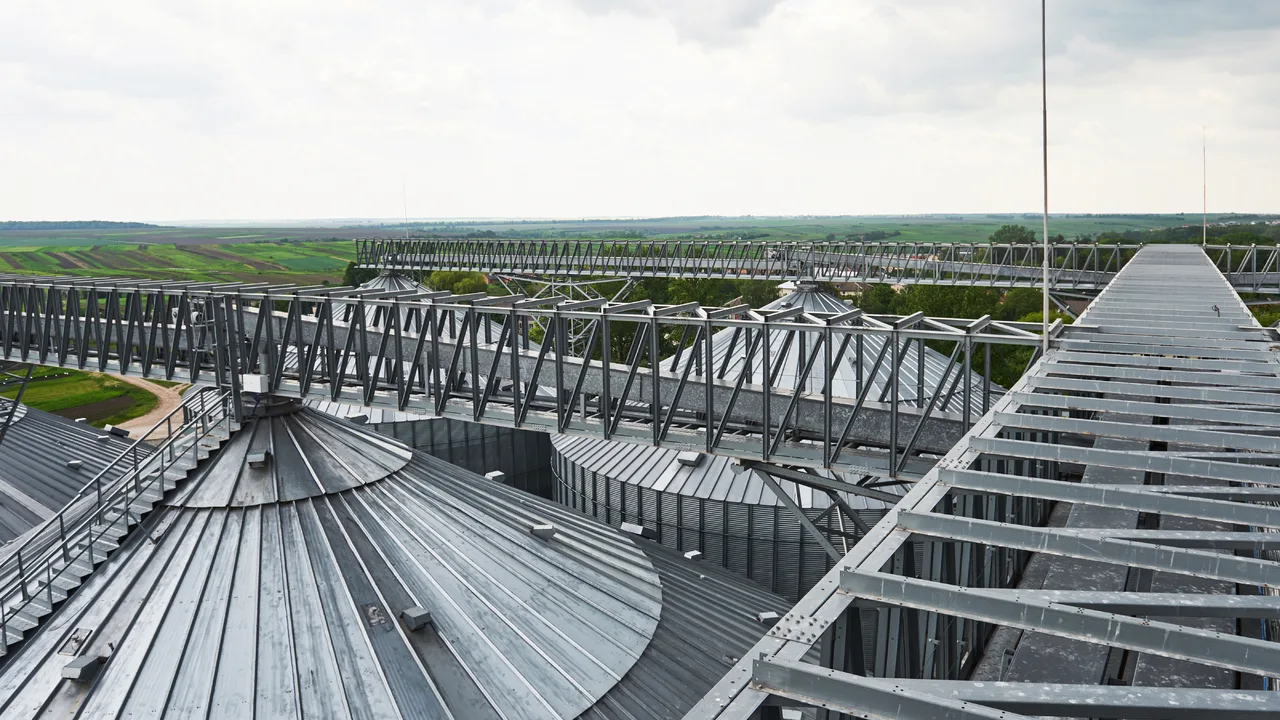

A steel structure factories refers to an engineered building system that uses prefabricated steel components to form its main load-bearing framework. Designed for industrial-scale operations, it supports heavy machinery, production lines, and mechanical systems used in power plant construction. These factories are not limited to manufacturing plants—they’re also critical for supporting energy infrastructure such as turbine assembly halls and maintenance depots.

Main Structural Systems Used

- Portal Rigid Frames: Commonly used for turbine halls and boiler buildings; offer large clear spans and high rigidity.

- Truss Systems: Ideal for lightweight roofs and wide openings; optimize material usage while maintaining structural stability.

- Space Frames: Provide three-dimensional strength for complex energy buildings with multiple load points.

These structural systems allow engineers to design highly customized solutions according to the specific requirements of each power generation project. For example, gas-fired power plants may require elevated steel frameworks to support turbines and exhaust stacks, while renewable energy facilities may prioritize open, modular layouts for easy reconfiguration.

Key Features for Power Generation Facilities

Every energy project has unique operational demands. The modern steel structure factory meets these needs through intelligent design and specialized construction techniques. Below are the essential features that make steel buildings ideal for power plant construction and heavy industrial use:

| Feature | Description |

|---|---|

| Large Clear Spans | Provide unobstructed space for installing turbines, generators, and cranes in expansive turbine halls. |

| High Roof Clearance | Accommodates overhead cranes and tall process equipment essential for energy operations. |

| Reinforced Flooring | Supports heavy mechanical loads while ensuring vibration control during plant operations. |

| Corrosion Resistance | Protective coatings and galvanized steel prevent degradation in high-humidity or coastal locations. |

| Fireproofing Systems | Applied coatings and composite insulation improve safety in high-temperature environments. |

Steel Structure Factory in Power Plant Construction

Modern power generation facilities increasingly rely on the steel structure factory model to meet efficiency and sustainability goals. Prefabrication allows components to be produced simultaneously with site preparation, saving months in construction schedules. This method minimizes delays caused by weather, reduces labor costs, and ensures consistent quality control.

In conventional power stations, steel frames form the skeleton of turbine enclosures, boiler buildings, and fuel-handling areas. Their modularity enables quick assembly and disassembly, allowing maintenance teams to access critical systems without dismantling large sections of the structure. For turbine halls, the integration of overhead cranes and vibration isolation systems allows for safe handling of massive machinery during installation and repair.

Integration with Renewable Energy Infrastructure

The adaptability of steel extends beyond thermal or gas-fired plants. In renewable energy projects—such as solar farms, wind turbine assembly facilities, and battery storage centers—steel buildings offer the same reliability and scalability. Prefabricated steel warehouses can serve as component storage, inverter control rooms, or logistics hubs for large-scale wind and solar operations.

Hybrid plants that combine multiple energy sources, like wind and solar, also benefit from steel’s modularity. The steel structure factories framework allows engineers to design flexible layouts that can integrate electrical substations, energy storage units, and maintenance workshops under one roof, reducing footprint and operational costs.

Advantages of Steel Structure Factories for Energy Projects

Implementing a steel structure factories in power plant construction delivers numerous technical and economic advantages. The combination of precision engineering, modular assembly, and high-performance materials transforms how modern energy projects are executed. Below are the core benefits that make steel structures indispensable in the global power industry.

Speed and Efficiency

Time is one of the most valuable resources in energy development. Prefabricated steel structure factories components can be produced off-site while foundation and groundwork proceed simultaneously. This parallel workflow can shorten total project timelines by up to 40%, an advantage especially critical for utility-scale installations. The ability to fast-track construction ensures earlier commissioning, faster returns, and minimized downtime in power plant construction.

Strength and Safety

Steel’s high tensile and compressive strength provides superior safety margins in extreme environments. In turbine halls and generator buildings, the framework must endure vibrations, heat, and pressure. Steel’s elasticity and toughness enable it to absorb energy from mechanical loads without cracking or warping. Moreover, modern engineering standards ensure that every steel structure factories meets strict seismic, wind, and fire protection codes.

Sustainability and Environmental Impact

Environmental sustainability is central to the future of energy. Steel supports this objective through recyclability and efficient material usage. Unlike concrete structures, which require high carbon output during production, steel can be reused or melted down for new applications. Prefabrication also generates minimal onsite waste, aligning with the low-emission goals promoted by Energy.gov and international green-building standards.

Adaptability and Expansion

One of the greatest strengths of a steel structure factory lies in its flexibility. Energy facilities evolve constantly—adding new turbines, switching fuel systems, or integrating renewable components. Steel frameworks can be easily expanded or reconfigured without interrupting existing operations. For example, additional bays can be bolted onto turbine halls or new mezzanine levels added for control rooms and cable trays.

Economic Benefits of Steel Structure Construction

Beyond technical performance, the economic impact of using a steel structure factory is substantial. Energy projects operate on tight budgets and schedules, and any delay directly affects profitability. The efficiency of steel construction significantly reduces both capital expenditure (CAPEX) and operational expenditure (OPEX).

- Reduced Installation Costs: Fast assembly and lower labor requirements minimize overhead costs during power plant construction.

- Low Maintenance: Coated steel components require minimal repainting or reinforcement, cutting lifecycle expenses.

- Longevity: A properly maintained steel structure factories can last over 50 years, outperforming traditional construction materials.

- Enhanced Asset Value: Stronger, safer, and eco-friendly facilities improve investor confidence and long-term operational returns.

Case Studies and Industry Insights

Several energy facilities worldwide have successfully adopted steel structure factories designs, demonstrating their efficiency and versatility across diverse environments.

1. Combined-Cycle Power Plant Turbine Hall

In a modern combined-cycle plant, the turbine hall must accommodate massive gas turbines and generators while maintaining precise alignment and vibration control. A steel structure offers the necessary rigidity and flexibility to house this equipment. Prefabricated columns and roof trusses accelerate installation, enabling project completion months ahead of schedule.

2. Wind Turbine Component Workshop

Wind energy development requires specialized workshops for blade fabrication and gearbox assembly. A large-span steel structure factories provides ideal conditions—ample space, crane integration, and high roof clearance—to handle these oversized components. The modular design also allows for future expansion as production capacity increases.

3. Solar Power Logistics Warehouse

Solar farms often rely on dedicated steel warehouses for storing panels, inverters, and electrical components. These warehouses utilize truss or portal-frame designs to achieve optimal space efficiency. With reflective roofing and natural ventilation, they maintain controlled temperatures that protect sensitive photovoltaic equipment.

Smart Technologies in Steel Construction

The next generation of steel structure factories design incorporates digital innovation. Building Information Modeling (BIM) enables seamless coordination between engineers, fabricators, and contractors. Through 3D simulation, potential clashes are detected early, minimizing costly rework. Structural sensors and IoT-based monitoring systems are also being integrated to track load performance and environmental conditions in real time.

Digital Twin Applications

Digital twin models replicate the behavior of actual buildings, allowing operators to simulate structural responses during extreme conditions. For turbine halls in power plant construction, this means predicting stress points and adjusting maintenance schedules proactively. These innovations significantly improve operational safety and extend the service life of each structure.

Future Outlook: Steel and the Energy Revolution

The role of the steel structure factories in the energy sector will only grow stronger as the world transitions toward cleaner power generation. As renewable energy capacity expands, the need for efficient, modular, and sustainable industrial buildings becomes even more critical. Steel fabrication aligns perfectly with this vision—fast, recyclable, and adaptable to any form of energy production, from fossil fuels to green hydrogen.

Emerging technologies such as AI-assisted design, robotic welding, and low-carbon steel production will further enhance the environmental and economic benefits of steel structure. The integration of smart systems into factory design will make future energy infrastructure more intelligent, interconnected, and resilient than ever before.

Conclusion

In the modern energy landscape, the steel structure factories represents far more than just a building—it’s a foundation for progress. Its combination of speed, durability, and flexibility makes it an indispensable element of power plant construction and industrial energy systems. From massive turbine halls to renewable energy workshops, steel continues to define the infrastructure that powers our world.