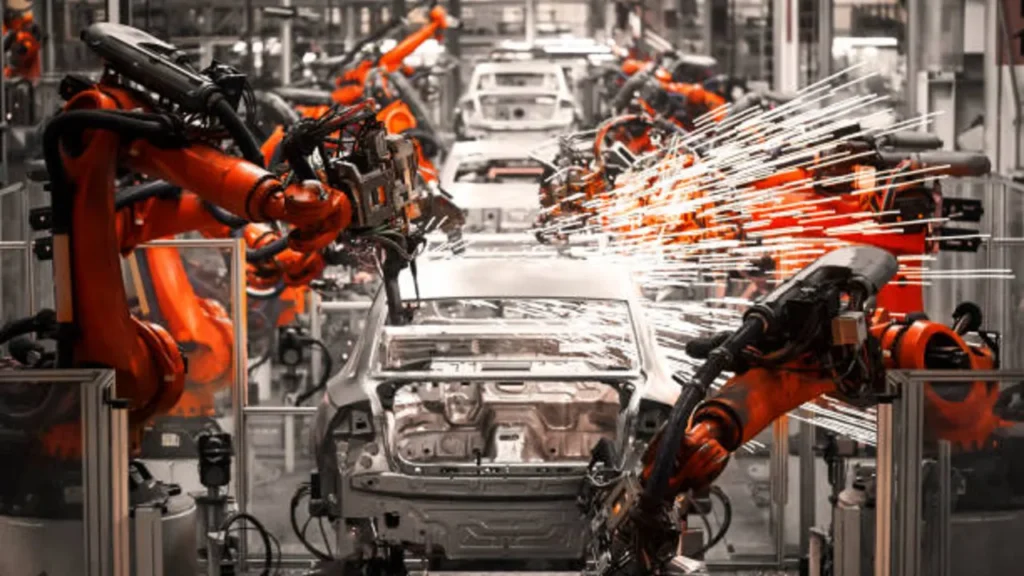

In an era where manufacturing is rapidly transitioning toward automation and digital integration, the concept of quality control manufacturing has taken center stage. Modern factories are no longer satisfied with traditional inspection methods — they demand real-time data, automated precision, and continuous improvement driven by intelligent systems. From sensors to precision testing equipment, every aspect of quality control is evolving to meet the requirements of Industry 4.0.

Why Quality Control Defines Modern Manufacturing

Today’s global manufacturers face immense pressure to achieve high productivity while maintaining impeccable quality standards. Whether producing microchips, engines, or steel components, consistency is key. Quality control manufacturing ensures that each product meets specifications, minimizes waste, and reduces rework costs.

The modern approach is no longer reactive — where defects are found after production — but proactive. Advanced sensors and data analytics enable predictive quality systems that can detect deviations early, preventing errors before they escalate. This shift represents a fundamental evolution in how manufacturers think about efficiency, precision, and sustainability.

The Evolution of Quality Control

Quality assurance has evolved from simple visual inspection to highly sophisticated, data-driven systems. In the early industrial era, inspection relied heavily on manual measurement and human experience. With the rise of automation, factories began implementing statistical process control (SPC) and machine-based monitoring to track deviations more accurately.

Now, under the umbrella of smart manufacturing, quality control manufacturing integrates artificial intelligence, IoT-enabled sensors, and cloud data analytics. This integration allows companies to move toward a “zero-defect” environment. Through feedback loops and automatic adjustments, production lines self-optimize — ensuring that quality standards are not just maintained but continuously improved.

Core Principles of Quality Control Manufacturing

Modern quality control relies on four main principles: detection, measurement, analysis, and correction. These stages work together to maintain consistent product performance and process reliability.

- Detection: Identifying variations or potential defects using sensors and imaging systems.

- Measurement: Quantifying product dimensions or material properties with precision testing tools.

- Analysis: Using statistical models to interpret process data and isolate root causes.

- Correction: Implementing process adjustments automatically or through operator intervention.

The integration of these principles allows factories to achieve real-time decision-making, enabling a culture of continuous improvement. For example, by linking quality control to digital production dashboards, teams can monitor performance indicators like defect rates, energy consumption, and equipment health — all from a single interface.

Process vs Product Control

A key distinction in quality control manufacturing is between controlling the process and controlling the product. Process control ensures that production variables such as temperature, speed, and pressure remain stable, while product control focuses on the end result — dimensions, strength, surface finish, or performance.

| Type | Focus | Example Tools |

|---|---|---|

| Process Control | Monitoring operational parameters | Pressure and temperature sensors, flow meters |

| Product Control | Inspecting final outputs | 3D scanners, tensile testers, coordinate measuring machines |

Sensors and Data Acquisition in Advanced QC Systems

At the core of modern quality control lies a network of intelligent sensors. These devices capture critical data points — from vibration to heat, from optical properties to surface irregularities — enabling systems to detect deviations in milliseconds.

For example, ultrasonic sensors can identify internal cracks in metal components, while laser displacement sensors measure microscopic variations in thickness. The rise of Internet of Things (IoT) has allowed these sensors to connect directly to centralized monitoring systems, creating a seamless data acquisition loop across the production line.

Through this setup, manufacturers can achieve unprecedented visibility over their processes. Real-time alerts inform operators the moment a variable exceeds its threshold, allowing immediate corrective action. This level of precision ensures that energy and material resources are not wasted, aligning quality assurance with sustainability goals.

Precision Testing and Measurement Technologies

Precision testing is the foundation of reliable quality control manufacturing. Whether in aerospace, automotive, or energy sectors, every component must meet exact tolerances. Cutting-edge measurement tools ensure that products conform to specifications within microns.

Common instruments include coordinate measuring machines (CMMs), laser scanners, and non-destructive testing systems such as X-ray and ultrasonic imaging. Each serves a specific role — dimensional accuracy, material integrity, and defect detection. These tools provide feedback to the central control system, closing the quality loop between inspection and production.

- Destructive Testing: Evaluates performance by applying stress until failure — useful for verifying material limits.

- Non-Destructive Testing: Uses imaging or acoustic methods to detect flaws without damaging components.

- Inline Precision Testing: Integrates sensors directly into the production line for real-time measurement.

Advances in automation have made precision testing faster and more accurate. Robotic arms equipped with laser or vision systems can inspect hundreds of parts per minute. These innovations minimize human error, lower inspection costs, and enhance throughput without compromising quality.

Continue to Part 2 → covering automation and AI, energy-intensive QC integration, digital twins, human roles, and the future of smart quality systems.