In today’s era of industrial modernization, automation in steel factories has redefined how structures are designed, fabricated, and assembled. By integrating robotics, digital control systems, and real-time data analytics, the modern steel structure factory has become a symbol of precision, speed, and sustainability. Automation not only improves production efficiency but also ensures consistent quality and worker safety—three pillars of competitiveness in the global construction industry.

Understanding Automation in Steel Factories

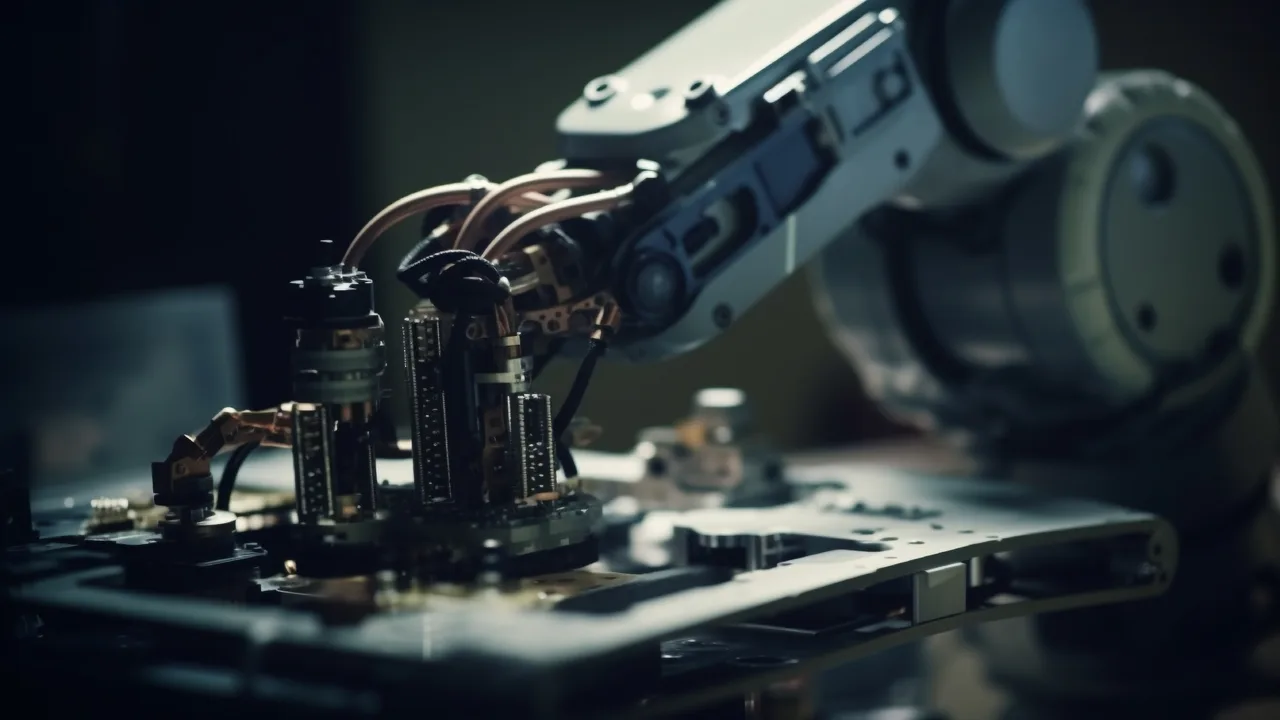

Automation in steel factories refers to the use of computer-controlled machinery and intelligent systems that perform repetitive or complex tasks with minimal human intervention. These technologies include robotic welding stations, automated cutting lines, and intelligent scheduling systems that link directly with engineering design software. The goal is to connect design, production, and quality control into one seamless digital workflow.

Core Technologies Driving Automation

- Robotics: Robotic welding arms and automated manipulators handle heavy steel members with precision and repeatability. Their sensors adjust parameters dynamically to ensure perfect weld penetration and alignment.

- IoT and Smart Sensors: Internet-connected devices monitor every stage of production—from plate cutting temperature to beam-line torque—allowing operators to track performance and detect anomalies instantly.

- Artificial Intelligence (AI): AI algorithms predict maintenance needs, optimize material flow, and generate real-time production analytics to boost production efficiency.

According to Siemens Industry, digitalized manufacturing lines can raise steel fabrication throughput by over 20 percent while cutting energy use by nearly a third. This demonstrates how smart automation delivers both economic and environmental advantages.

From Manual Fabrication to Smart Production

Traditionally, steel fabrication relied heavily on manual labor for cutting, drilling, and welding. These processes were time-consuming, labor-intensive, and prone to variation in quality. The rise of automation in steel factories has replaced these manual steps with programmable machines capable of continuous, high-precision work. Computer numerical control (CNC) systems now drive plasma cutters, beam lines, and drilling machines, reducing tolerance errors to less than one millimeter.

Modern factories integrate their CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) platforms. Once the design drawing is approved, production data automatically flows to machines for processing. This direct digital transfer minimizes human error and speeds up fabrication cycles—transforming the steel structure industry from traditional workshops into digitally managed production ecosystems.

Benefits of Automation in Steel Factories

Embracing automation in steel factories provides measurable benefits that reach far beyond faster production. By aligning robotics and analytics, companies achieve greater output, reduced waste, and safer workplaces.

1. Increased Production Efficiency

Automation ensures uninterrupted operation through shift-less production. Machines work continuously with minimal downtime, significantly shortening project delivery timelines. Real-time monitoring systems also allow supervisors to adjust speed and sequence based on actual job progress, improving throughput without sacrificing accuracy.

2. Quality Consistency

Every weld, cut, and joint meets exact specifications, guaranteeing structural reliability across large-scale projects. Automated inspection systems use lasers and cameras to verify dimensional accuracy and weld penetration, producing consistent results impossible to achieve manually.

3. Improved Workplace Safety

By letting robots handle heavy lifting, high-heat, or confined-space operations, automation reduces accident rates. Workers transition from risky physical tasks to supervisory and programming roles, enhancing both safety and career value.

4. Resource Optimization

Smart scheduling software and nesting algorithms minimize material waste during plate cutting. Energy-efficient motors and optimized torch paths further lower operational costs and environmental impact, making automation a core strategy for sustainability in the steel sector.

Robotics and Human Collaboration

Automation in steel factories does not eliminate the human factor—it redefines it. Collaborative robots (cobots) operate alongside technicians, handling repetitive actions while humans focus on precision assembly and quality judgment. This symbiotic relationship increases production efficiency and provides new upskilling opportunities for the workforce.

Integrating Automation into Steel Structure Projects

Automation’s impact extends beyond factory walls into real project execution. Through cloud-connected platforms, designers, engineers, and fabricators share live data, aligning design intent with actual fabrication outcomes. In a connected steel structure factory, sensors, AI software, and robotic tools communicate through a unified control center—creating the foundation for a truly intelligent construction supply chain.

Case Example: Automated Beam Production Line

In a modern automated beam line, the workflow starts with 3D model input from Building Information Modeling (BIM). CNC machines then perform cutting and drilling, followed by robotic welding and automatic surface finishing. Quality checks are executed by laser scanners before each component proceeds to painting and dispatch. The entire sequence runs under one digital dashboard, reducing total fabrication time by up to 40 percent compared to traditional methods.

Challenges of Implementing Automation

While the advantages of automation in steel factories are undeniable, the journey toward full digital transformation is not without obstacles. The most common challenges include high capital costs, complex system integration, and limited technical expertise within the workforce. Many small and mid-sized companies hesitate to adopt automation due to concerns over return on investment and training requirements.

Another challenge involves the interoperability of software and hardware systems. Different machines, sensors, and management platforms often use varying communication protocols, making integration a major technical hurdle. Without seamless data exchange, the promise of a fully connected steel structure factory remains incomplete.

Overcoming the Barriers

- Phased Implementation: Begin automation in critical bottleneck areas—like beam welding or CNC cutting—before scaling to full-factory integration. This staged approach helps spread investment and minimize production disruption.

- Workforce Training: Upskilling employees in robotics operation, PLC programming, and digital maintenance ensures smooth technology adoption and long-term sustainability.

- Data Standardization: Using open communication protocols (OPC UA, MQTT) promotes compatibility among machines and software systems, allowing for unified control and monitoring.

- Collaborative Partnerships: Partnering with automation technology providers and engineering consultants helps factories accelerate transformation with less trial and error.

Economic and Operational Benefits

Factories that embrace automation in steel factories experience not only operational improvements but also measurable financial gains. Through automation, manufacturers can increase output without proportional rises in labor or energy costs. Predictive maintenance reduces downtime by detecting machine wear before failure occurs, ensuring uninterrupted production schedules.

From a financial standpoint, payback periods for modern automation systems are increasingly attractive. Once robotic and digital control systems are installed, the consistent output and lower defect rates translate directly into higher profitability. Furthermore, automation enables manufacturers to handle complex, large-volume orders that would otherwise be difficult to deliver under tight deadlines.

Enhanced Production Efficiency Through Data

Real-time analytics platforms collect thousands of data points per minute from machines, sensors, and quality control units. This data empowers managers to make informed decisions based on live performance metrics. Trends in material usage, energy consumption, and cycle times become clear, enabling precise optimization strategies that continuously improve production efficiency.

Future of Automation in the Steel Structure Industry

The next stage of automation in steel factories will integrate advanced technologies that push the limits of intelligence and sustainability. Artificial Intelligence (AI), machine learning, and cloud connectivity are paving the way toward fully autonomous operations—where decision-making is driven by algorithms rather than human supervision.

Smart Integration with Building Information Modeling (BIM)

By linking BIM data directly to fabrication lines, factories can automatically translate digital designs into machine commands. When combined with ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems), production becomes synchronized with material supply, logistics, and project scheduling. This integration eliminates bottlenecks and ensures every fabricated component aligns perfectly with the construction plan.

Autonomous Machinery and Robotics

Emerging robotics technologies will soon enable cranes, forklifts, and inspection drones to operate autonomously inside steel facilities. These self-navigating systems will transport beams, weld assemblies, and even conduct visual inspections using AI-powered cameras. Such capabilities not only boost production efficiency but also reduce the risks associated with heavy material handling.

Green Automation and Sustainability

As environmental awareness grows, automation in steel factories is evolving to prioritize sustainability. Energy-efficient motors, smart lighting, and regenerative drive systems minimize power consumption. Meanwhile, advanced analytics identify opportunities for waste heat recovery and material recycling, aligning with global sustainability targets and ESG (Environmental, Social, and Governance) principles.

Global Examples of Smart Steel Structure Factories

Several leading steel manufacturers worldwide are pioneering the next generation of smart production. In China, Japan, and Germany, automated fabrication plants now feature AI-driven scheduling systems that coordinate hundreds of machines simultaneously. These facilities maintain real-time communication with suppliers and clients, ensuring every component is tracked from raw material to delivery.

For instance, automated workshops in East Asia employ laser scanning and robotic assembly to produce steel structures for bridges, industrial warehouses, and high-rise buildings. Each step—from digital modeling to final inspection—is data-driven, ensuring unmatched precision and traceability.

Workforce Transformation and Digital Skills

One of the most overlooked aspects of automation in steel factories is the evolution of the human role. Instead of manual labor, workers now manage machines, interpret data, and maintain complex systems. This shift creates demand for new skills in robotics programming, system analytics, and mechatronics. Many forward-thinking companies invest in continuous learning programs to prepare their employees for the new industrial era.

The future steel structure factory will not replace humans but empower them. Collaboration between humans and intelligent machines creates a safer, more efficient, and more rewarding workplace. As automation technology continues to advance, this partnership will define the competitiveness of global steel manufacturing.

Conclusion

Automation in steel factories has evolved from a productivity tool into a strategic necessity for the global steel industry. By combining robotics, AI, and digital connectivity, factories can achieve unprecedented levels of production efficiency, quality assurance, and sustainability. The transformation extends beyond manufacturing—it reshapes how industrial projects are planned, executed, and delivered.

In an increasingly competitive market, the steel structure factory that embraces automation will stand at the forefront of innovation and industrial excellence. As technology continues to evolve, full-scale smart fabrication represents the next frontier of progress—merging efficiency, intelligence, and sustainability into a single powerful system.